Even though we may not pay much attention to them in our daily lives, grilles play a vital role in organizing different areas of our homes. The structures using grilles come in various types, often shaped from steel wires and coated to prevent rust.

The use of steel wires makes manufacturing grilles easy and flexible for adjustments. This makes steel grilles popular for their versatility and cost-effectiveness in various applications.

The advantages of using steel wire in making grilles

Strength and Durability

Flexibility

Cost-Effective

Steel wire is strong and can withstand general usage.

Steel wire is flexible, making it easy to shape according to requirements.

Manufacturing grilles with steel wire often has lower costs.

Low carbon steel wire is commonly used in making grills. The preferred wire sizes for making grills are typically in the range of small to medium, allowing for easy shaping of the grill and providing sufficient strength for usage.

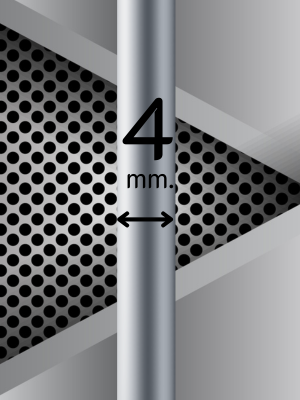

The preferred wire sizes are usually in the range of 3 millimeters to 8 millimeters, suitable for creating grills with thickness and strength. Additionally, the wire sizes used in making grills depend on the structural design of the specific product.

Most popular size of steel wire

3 mm. in diameter

4 mm. in diameter

5 mm. in diameter

Low carbon steel wire 9D

This product obtained by drawing and reducing the size of low-carbon steel wire to achieve the desired diameter as requested by customers.