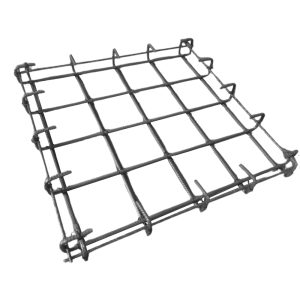

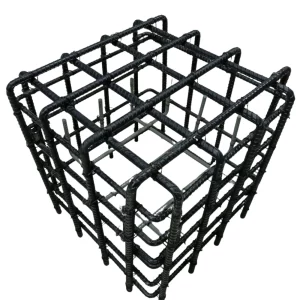

Our company meticulously crafts steel binding wires (TIS no. 138-2562) using low-carbon steel wire. We initiate the process by drawing and resizing the wire to attain a precise central diameter of 1.25 mm. Subsequently, our skilled team bundles the wire into coils, adhering to specific specifications tailored to meet diverse construction needs. We then apply a thorough vacuum annealing process to enhance the wire’s properties.

This meticulous manufacturing approach ensures that our black annealed wire exhibits exceptional qualities. Its soft and pliable nature sets it apart, making it a superior choice for a wide array of construction projects. The versatility of our wire extends beyond its physical characteristics, as it offers ease of handling and adaptability to various applications on construction sites.

Our commitment to quality goes hand in hand with our dedication to meeting industry standards. The steel binding wires we produce not only meet but exceed TIS no. 138-2562 specifications. Our manufacturing process prioritizes precision and efficiency, resulting in a product that consistently performs at the highest level.

Furthermore, our customer-centric approach extends to providing customizable options. Clients can specify coil configurations and dimensions, allowing us to tailor our steel binding wires to unique project requirements. This flexibility ensures that our products seamlessly integrate into diverse construction scenarios, enhancing efficiency and overall project success.

In conclusion, our actively produced steel binding wires stand as a testament to our commitment to excellence. From the careful drawing and resizing process to the precise bundling and vacuum annealing, every step reflects our dedication to delivering top-tier products for the construction industry. Choose our black annealed wire for a reliable, versatile, and high-quality solution that exceeds expectations.